Impact-Site-Verification: b3b85574-362c-46bf-906e-e88f9b0ad70b

Building your own woodworking bed frame is one of the best DIY projects you can do! Not only will you create a beautiful piece of furniture for your bedroom but you’ll also make something that can last for generations.

In fact, a recent survey found that 78% of handcrafted wooden bed frames last over 25 years with proper care.

Whether you're tackling your first woodworking project or taking on a new challenge, this guide has you covered.

You'll learn step-by-step how to build a custom bed frame that suits your style.

With clear instructions, you'll create a sturdy, beautiful piece that lasts.

Many leading furniture and DIY experts, including Ben Strano at Fine Woodworking, Andy Rae at Woodcraft Magazine, and Leeron Hoory at Popular Mechanics, emphasize the importance of using high-quality lumber and precise joinery techniques for long-lasting bed frames.

Selecting kiln-dried wood helps prevent warping over time, ensuring structural integrity.

Materials and Tools You’ll Need

Before you start your DIY bed frame project, you need to gather the right materials and tools for success. The quality of your materials impacts the durability and look of your finished piece.

For most wooden bed frame plans, you’ll need:

- Lumber: 2x4s, 2x6s, 1x3s and possibly 4x4s for posts

- Plywood: 3/4" plywood for platform bed woodworking plans or slat supports

- Fasteners: Wood screws (various sizes), bolts for main connections, wood glue

- Finishing supplies: Sandpaper (various grits), wood stain, clear finish, brushes

Essential tools are:

- Table saw or circular saw

- Drill/driver with bits

- Measuring tools (tape measure, square, level)

- Clamps (various sizes)

- Sander

- Chisels (for traditional joinery)

If you have the budget, specialty tools like a pocket hole jig, doweling jig or router can make certain tasks much easier, especially when creating bed frame joinery that ensures stability. If you’re working with limited tools, pre-cut lumber from your home center can make the process much simpler.

Choosing the Right Wood for Your Bed Frame

The wood you choose is the foundation of your project and significantly affects the look and longevity. When deciding between hardwood vs softwood for bed frames, consider these:

Hardwood options like oak, maple, and walnut offer great durability and beautiful grain patterns. Oak is strong and has a distinctive grain that takes stain well.

Maple is smooth and consistent and perfect for modern designs. Walnut is pricier but delivers a rich dark color and premium feel that many woodworkers love.

For environmentally conscious woodworkers, explore our guide to eco-friendly bed frame materials including bamboo and reclaimed wood to make your DIY project more sustainable.

Softwood alternatives like pine and cedar are more budget-friendly wood bed frame materials. Pine is widely available, easy to work with and takes stain well, but dents more easily than hardwoods. Cedar resists moisture and insects naturally and is good for humid environments.

When selecting lumber, pay attention to wood moisture content for furniture, aiming for properly dried wood with 6-8% moisture content.

Choose boards with minimal defects, straight grain, and few knots, especially for structural components.

Consider eco-friendly bed frame materials like FSC-certified wood or explore reclaimed wood bed projects for environmental sustainability and unique character.

Can't decide between light and dark wood tones? Our comprehensive guide to wood bed frames in various finishes can help you visualize the final result.

Planning Your Bed Frame Design

Proper planning prevents poor performance, especially for big projects like handcrafted bed frames.

In the design phase, your vision comes together, setting the foundation for a successful woodworking project that balances style and functionality.

Bed Size Dimensions

Start by determining the exact dimensions based on your mattress size:

- Twin bed frame measurements: 38" x 75"

- Full-size bed frame plans: 54" x 75"

- Queen-size bed frame dimensions: 60" x 80"

- King-size bed frame plans: 76" x 80"

- California king bed dimensions: 72" x 84"

Add 2-3 inches to each dimension for bedding and mattress clearance. Height is just as important—platform beds sit 14-18 inches from the floor, while traditional frames with box springs can reach 25 inches or more.

Consider your own height and mobility needs; taller people might prefer higher frames, while those with mobility issues might benefit from lower profiles.

If you’re designing for children, factor in growth and potential mattress upgrades as they mature.

While building your own bed frame is rewarding, understanding what makes high-end frames exceptional can elevate your design. For inspiration, explore our guide to luxury bed frame features worth incorporating into your DIY project.

Bed Frame Style

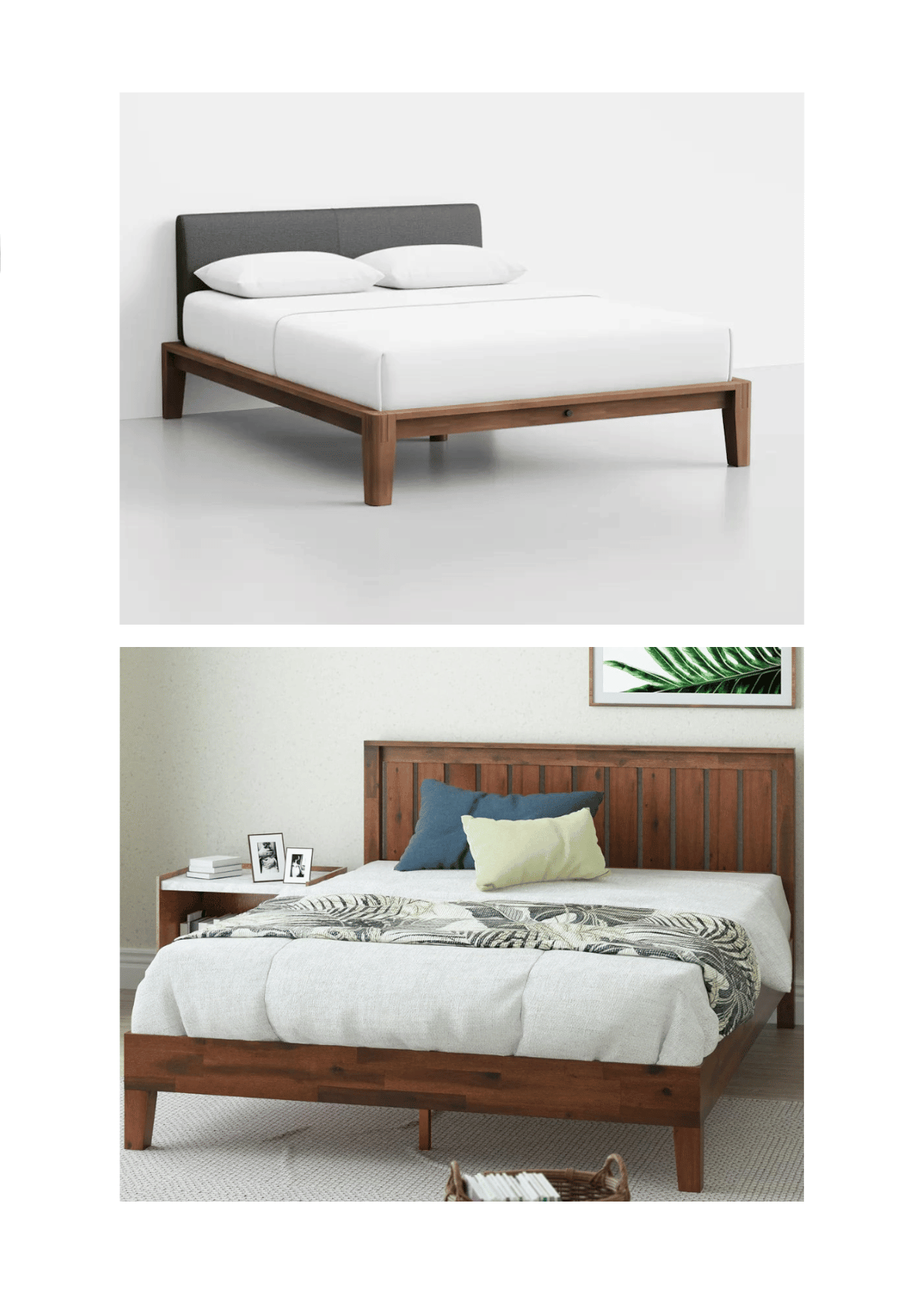

Your bed’s design should match both your style and practical needs. Popular custom bed frame design options are:

- Platform bed: Clean, low-profile design without a box spring

- Four-poster bed construction: Vertical posts at each corner

- Canopy bed frame construction: Four-poster with top rails for fabric* Storage bed: Includes drawers underneath for space maximization

- Floating bed frame design: Creates an illusion the bed is floating

- Japanese-inspired frames: Low, minimalist design with clean lines

- Rustic bed frame ideas: Incorporates natural elements or reclaimed wood

- Modern platform bed plans: Emphasizes simplicity and geometric forms

Each style presents different construction challenges and opportunities for personalization. Which elements resonate with your style and the existing decor in your bedroom?

Traditional bed frame styles often have ornate details and big headboards, while minimalist designs have clean lines and functional simplicity.

Creating Detailed Plans

Before cutting your first board, develop detailed plans to be your guide. Start with rough sketches that capture your vision, then refine those into scaled drawings with measurements. Include:

- Front, side, and top views with all dimensions marked

- Detailed joinery specifications for each connection point

- Cut list with lumber dimensions, quantities, and purpose

- Assembly sequence notes to guide your build

- Hardware placement and special feature details

Consider using woodworking software for precision or research existing bed frame plans online that you can modify to suit your needs.

Many woodworkers find it helpful to create full-size templates for complex curves or joinery using cardboard before committing to expensive lumber.

When designing your frame, consider the type of mattress you'll use. If you're planning to pair your DIY frame with a mattress with adjustable firmness, ensure your support system accommodates these specialized designs

Structural Considerations

The structural integrity of your bed frame determines its safety and longevity. For queen-size bed frames and larger, include a center support beam installation with legs that reach the floor.

This prevents the middle-of-the-night sag and ensures proper wood bed frame weight capacity. Consider these structural elements:

- Support slats should be no more than 3-5 inches apart for proper mattress support

- Corner reinforcement using brackets or additional blocking prevents wobbling

- Headboard attachment methods should allow for a secure connection to the frame

- Knockdown hardware for beds larger than full size makes moving and assembly easy

- Floating designs require hidden support systems that maintain the visual effect while providing the necessary strength

Take into account the weight distribution of sleepers and design with a safety margin—most queen beds should support at least 500 pounds, while king frames should support 600 pounds or more.

By planning these structural elements during the design phase you can create a bed frame that will last for decades without squeaks.

Step-by-Step Process

Trusted DIY platforms like The Spruce and Family Handyman recommend reinforcing bed slats with metal brackets for enhanced weight support.

This technique, also highlighted by Woodcraft Magazine, extends the lifespan of wooden bed frames by preventing slat shifting.

Now let’s break down the build process into steps:

- Cut your lumber: Cut all pieces according to your cut list. Cut long for dimensional accuracy, then trim to final size. Use a jointer and planer, if available, to create square, flat boards.

- Make your joinery: The strength of your bed frame relies on good connections. Choose from:

- Mortise and tenon bed joints (traditional, very strong)

- Pocket hole joinery for beds (fast, beginner-friendly)

- Dowel joinery bed frame (strong, moderate skill)

- Simple butt joints with reinforcement plates (easiest)

- Assemble the frame: Start with the headboard and footboard construction, then the side rails. When attaching rails to posts, make sure everything is square by measuring diagonals. Apply wood glue to all joints before fastening.

- Install support system: Create your bed slat support system or platform surface. Install the center support beam for larger beds first, then the slats or platform. Space the slats 3-5 inches apart for proper mattress support. Different mattresses require different support structures. For example, if you're considering a specialized mattress like the Prana mattress for your custom frame, you'll want to ensure your slat spacing meets the manufacturer's specifications.

- Sand thoroughly: Start with coarse (80-100) then progress to medium (120-150) and fine (180-220) grits. Pay attention to edges and areas that will be touched frequently.

- Apply finish: Choose between wood staining for bed frames or natural finishes. For durability, apply multiple thin coats rather than one thick coat and sand lightly between applications.

Before finalizing your design, confirm compatibility with your mattress type. Modern mattresses like the Thuma have specific support requirements that your DIY frame should accommodate for optimal comfort and longevity.

Advanced Joinery

Strong connections are key to preventing bed frame squeaks and stability. While simple methods work, traditional joinery offers both strength and craftsmanship:

Mortise and tenon joints are the gold standard for bed frame construction. This method creates a strong connection by fitting a projecting tenon from one piece into a corresponding mortise (hole) in another. Time consuming but can last centuries if done properly.

Dovetail joinery provides excellent resistance to pulling apart making it ideal for drawers incorporated into bed frames with storage drawers. Challenging to master but both strong and pretty.

If you want a balance between traditional and modern pocket hole joinery is the way to go. A pocket hole jig helps drill angled holes for screws to create strong connections hidden from view.

The key to good joinery is precision. Whatever method you choose, make sure it fits tight and use the right glue. For bed frame reinforcement techniques, consider adding corner blocks to butt joints or metal brackets at stress points.

Adding Custom Details and Features

Need design inspiration? Consider how celebrity bedroom styles and custom bed frames incorporate unique elements that you could adapt for your own woodworking project.

This is where your handcrafted bed frame gets unique. Consider these:

Headboard ideas range from simple flat panels to elaborate carvings. Beginners can get an elegant look with a frame-and-panel design without advanced skills. More experienced woodworkers can explore hand-carved bed details or integrated lighting.

Storage solutions add functionality to your bed frame. Think:

- Under-bed drawers on soft-close slides

- Bookcase headboards for bedside storage integration

- Hidden compartments for valuables

- Floating shelves attached to the headboard

Consider distressing, wire brushing or metal accents to achieve the weathered look of a rustic bed frame. Clean lines and minimal ornamentation is modern for platform bed plans.

When adding these features, make sure they don’t compromise the structure of the frame and that decorative elements are securely attached so they don’t come loose later.

If you're drawn to a more weathered, country aesthetic, check out our collection of rustic and pallet bed frame designs for inspiration on creating a cozy bedroom centerpiece.

Finishing Your Bed Frame

Finishing transforms raw wood into a beautiful, protected surface. This multi-step process takes time but delivers great results:

- Preparation: Sand all surfaces to 180-220 grit. Vacuum and tack cloth to remove dust.

- Coloring: If desired, apply wood stain according to manufacturer’s instructions. Apply pre-stain wood conditioner to softwoods for best results to prevent blotchiness. Test stain on scrap pieces from your project first.

- Protection: Choose between water-based vs oil-based finishes:

- Water-based finishes dry fast, have low VOCs, and maintain the wood’s natural color

- Oil-based finishes have a warmer tone and better durability but longer drying time

- Application: Apply 3-5 thin coats of clear coat finishes for wood, sanding lightly with 320-400 grit between coats. For a professional finish, consider:

- Wipe-on polyurethane for ease of application

- Spray finishes for the smoothest results * Traditional hand-rubbed oil finishes for a natural feel

Let the finish cure completely before using your bed. Depending on the product, this may take several days to a week. The time invested here will pay off in durability and looks.

Structural Integrity

A pretty bed that collapses is no bed at all. Taking steps to stabilize is crucial:

For larger beds (queen size and up) a center support beam with legs to the floor is a must. These supports prevent sagging which can damage the frame and mattress over time.

Pay attention to bed frame construction techniques for corners and rail connections as these are the stress points. Use the right fasteners like bed bolts or heavy-duty screws not just wood glue for critical connections.

If you plan to move, design your frame for disassembly. Knock-down bed frame designs use specialized hardware for repeated assembly and disassembly without weakening the structure.

Test for stability by applying pressure to different areas of the assembled frame. Fix any wobbling immediately by adding reinforcement where needed. Preventing bed frame squeaks is easier during construction than after; apply wax to wood-on-wood contact points and make sure fasteners are tight.

Whether you choose to build your own bed frame or purchase one, understanding what makes a quality dark wood bed frame or wood box spring will help you create a beautiful, durable sleeping space.

Conclusion

Building your own woodworking bed frame is a fulfilling project that combines practical skills with artistic expression.

With the right tools, quality materials, and the detailed steps outlined in this guide, you'll be able to create a beautiful, sturdy bed frame that will serve you well for decades to come.

Remember that patience and attention to detail are your best friends throughout this process. Don't rush—each carefully executed step brings you closer to a bed frame you'll be proud to display in your home and perhaps even pass down to future generations.

Your handcrafted bed frame deserves to be paired with a mattress that highlights your craftsmanship.

Consider how your design will work with various mattress types, from traditional innerspring to specialized options like the Sealy Posturepedic Plus Hybrid for the perfect bedroom ensemble.

Ready to get started? Gather your materials, set up your workspace, and begin the rewarding journey of crafting your very own custom bed frame!

FAQs

What’s the best wood for a beginner’s first bed frame project?

Pine is perfect for beginners – it’s affordable, easy to find, easy to work with, and forgiving of mistakes while still looking great when properly stained and sealed.

How much should I budget for a queen-size wooden bed frame?

Expect to spend $200-500 for materials depending on the wood (pine vs hardwood) and $50-100 for hardware and finishes. Using reclaimed wood or repurposing lumber can save you a lot of money.

Do I need special tools to build a good bed frame?

While special tools help, you can build a strong bed frame with basic tools: circular saw, drill, measuring tools and sander. Pocket hole jigs ($40) make joinery a breeze for beginners.

How do I stop my bed frame from squeaking over time?

Use proper joinery, apply paste wax to wood-on-wood contact points, ensure all fasteners are tight, and install center supports for larger beds. Check and tighten hardware periodically.